The Brick Brace Safety System – Full Set – Price includes free delivery within the United Kingdom – We also ship to the United States and Canada (US and Canadian shipping costs are weight based and shipping prices are calculated at checkout) – For other international/overseas orders, please contact us directly for a shipping quotation.

Brick Brace – Full Set

£320.00

Description

THE AWARD WINNING

BRICK BRACE SAFETY SYSTEM

FULL SET

–

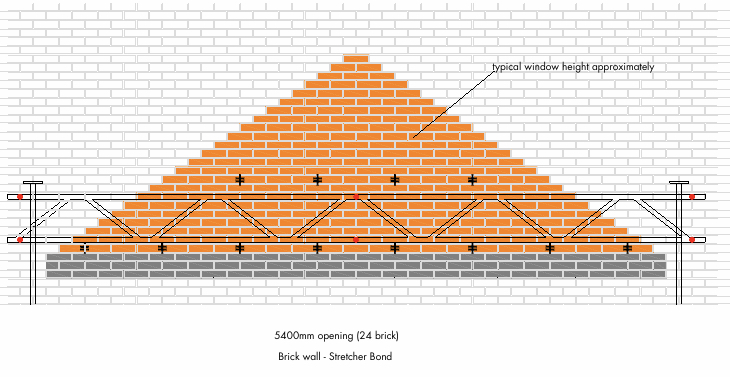

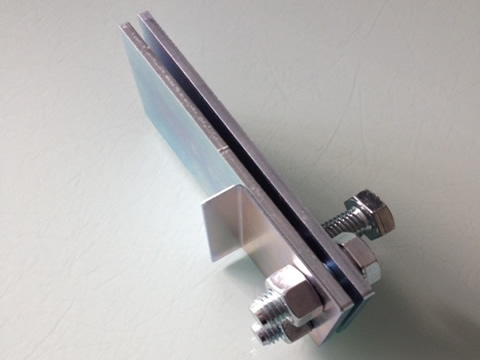

The Brick Brace is designed to give superior results with a safer fitting/working access and when used in-conjunction with existing propping methods the Brick Brace supports all of the un-held masonry in between props and also helps to avoid collapse through overloading.

–

12 safety tools, 12 hooks, 6 half couplers, anchor bolts, prompt UK delivery, detailed instructions, help-line, masonry weight awareness chart and VAT.

(Scaffold tube/beam not included)

30 DAY FREE TRIAL

GUARANTEED, SAFER, SUPERIOR & EASIER MASONRY ALTERATIONS

–

Full Set Procedure

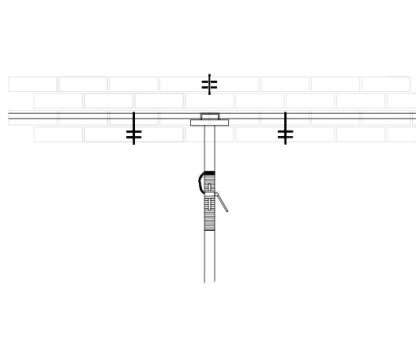

1. Drill & fit 2 couplers at both ends, 120mm past the opening & measuring 120mm & 520mm above the opening & also central at 120mm & 520mm.

2. Fit the Aluminium Scaffold beam and tighten couplers. Fit suitable sized Acrow props at either end.

3. Remove the required joints; maximum of three bricks apart in a cement mortar mix and a maximum of two and a half bricks apart within a weak or lime mortar mix.

4. Fit hooks over the tube at the drilled-out perp positions, fit safety tools into prepared perps, remove both nuts, secure hooks onto tools, refit nuts and tighten the tools.

5.Reinstate a missing load-point by fitting further single safety tools across the broken triangle.

Support 100% of the masonry above the opening, gain further fitting space, reduce repair time and achieve a guaranteed superior and safer finish.

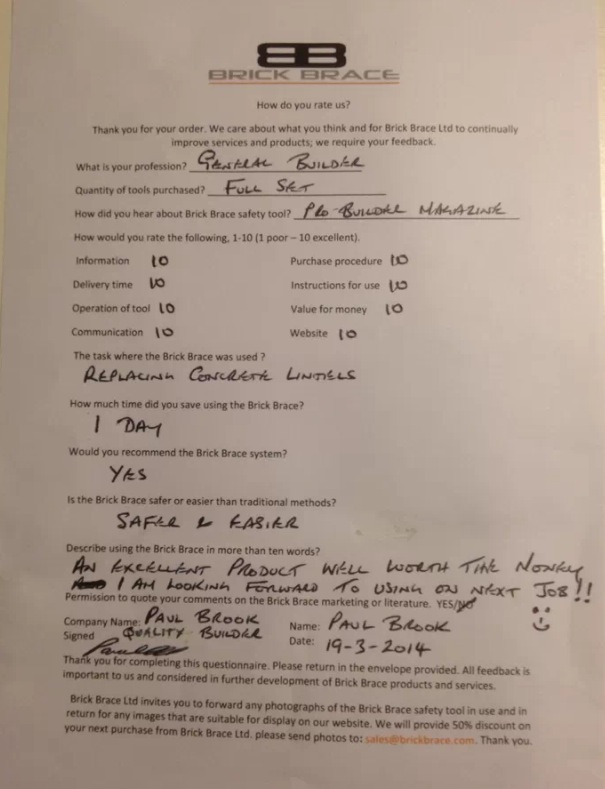

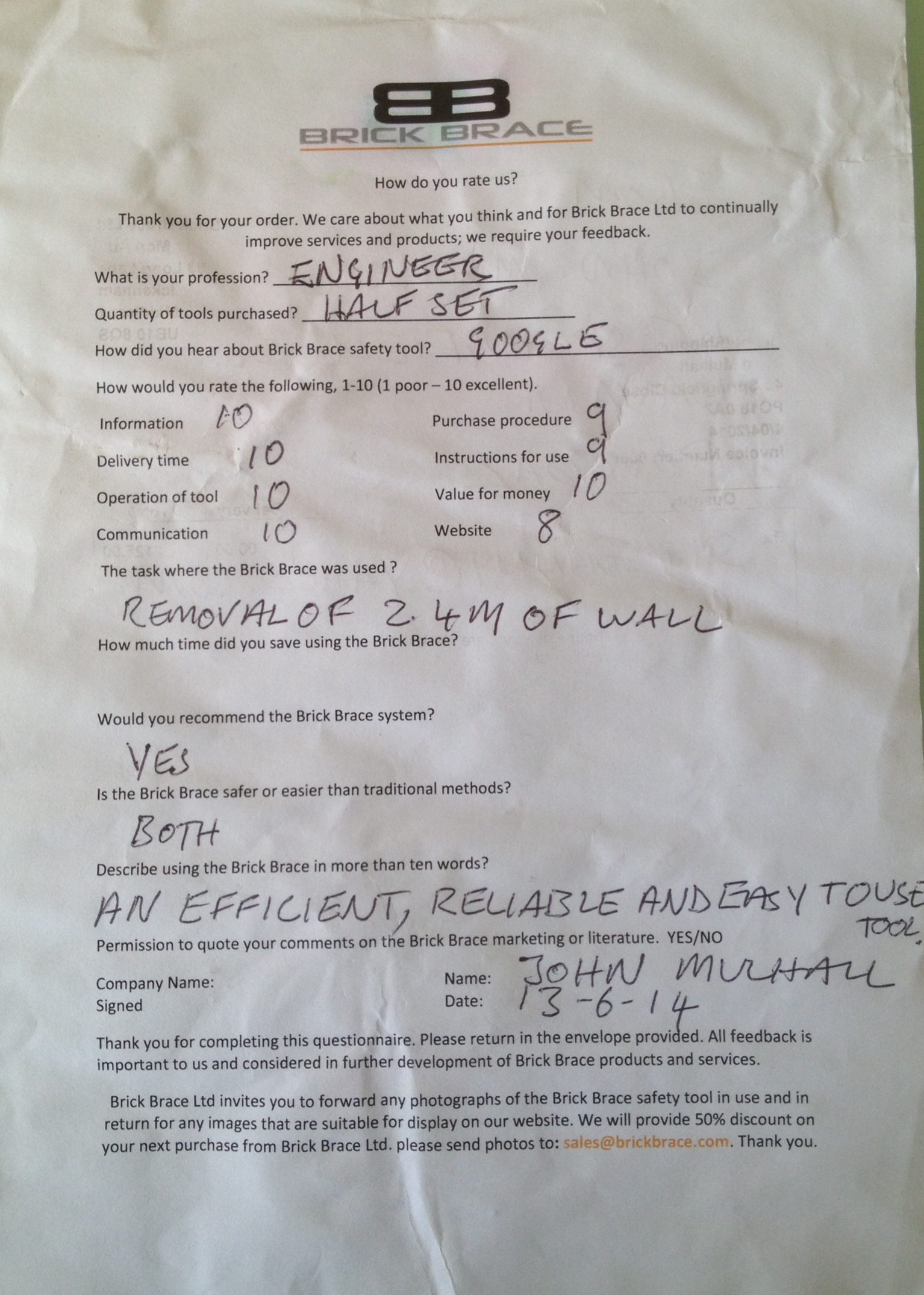

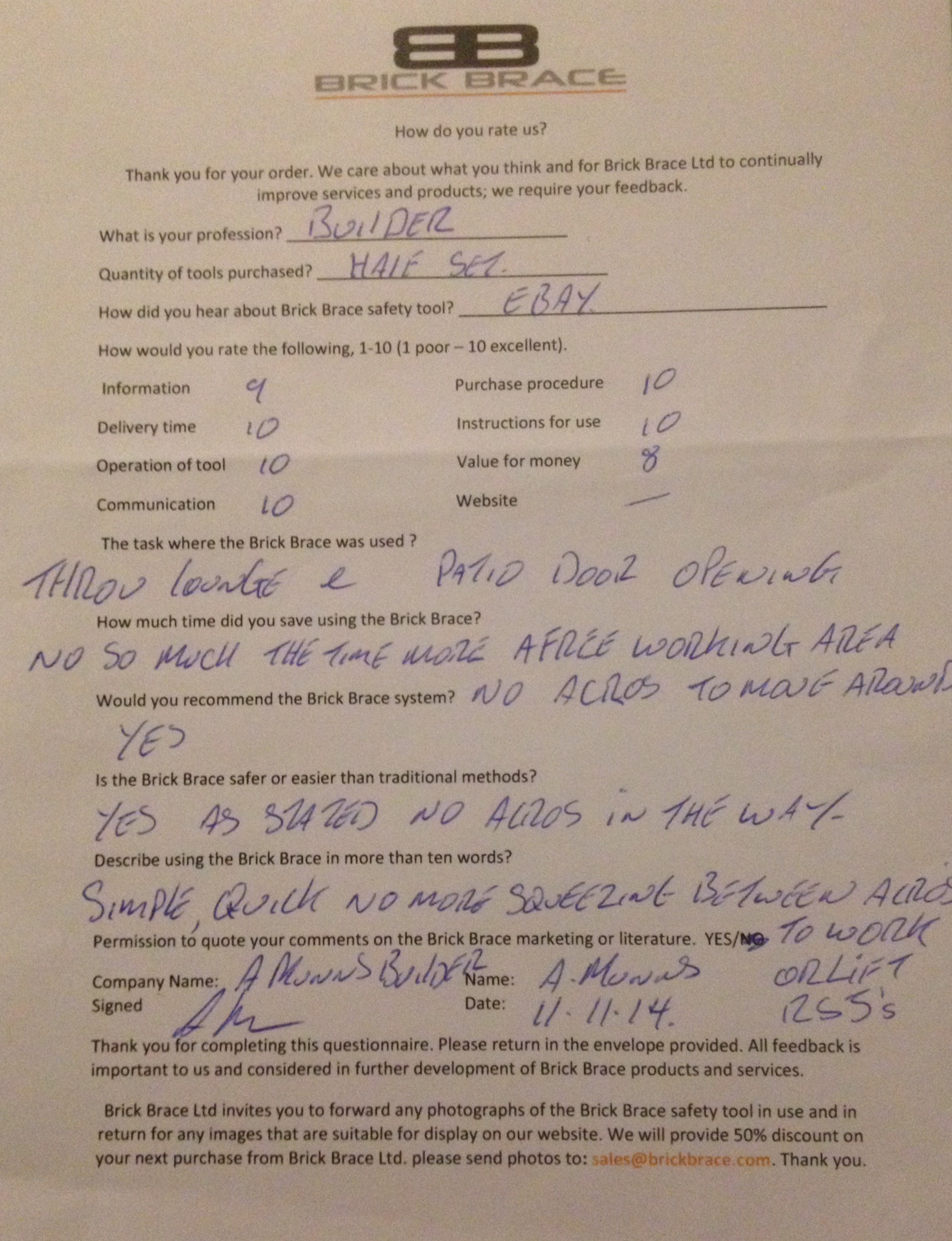

BRICK BRACE FEEDBACK

Mr S. Dunaway

(Builder, Surrey)

Top quality product.

“After taking the time to read and understand what the Brick Brace has to offer, I can now appreciate the impact this system can have on improving the safety of structural alterations.

After all structural alterations are the only general construction based procedures where NO training or advice is offered to any tradesman”.

“For me, Brick Brace is not just a product; it has provided an understanding of the task, with clear guidance on the limitations of all the equipment.

I also received very helpful advice and instructions from the guys at Brick Brace regarding my own project.

I challenge you all to find another company so invested in your own safety when it comes to structural alterations”.

–

We Are Here To Help You Adapt!

For unbiased advice regarding any masonry alterations task contact us;

Tel; 01895 546405

Or

Call Anthony On; 07545 462463

E-mail; sales@brickbrace.com

To help us help you, please read our propping guide to ensure you give us sufficient information of your task.

Or

Book A Brick Brace Demonstration On your own project, from as little as £720.00, Includes ½ day training, the Brick Brace Full Set and VAT.

–

We created the Brick Brace to provide further options and to ensure future generations are taught correctly.

BRICK BRACE BENEFITS

Simple to adapt to

–

Improves Masonry Alterations knowledge

–

Providing further temporary support options

–

Keyhole surgery for face brickwork

–

Full access to the task

–

Ensures future generations are taught safely & correctly

–

Use at any height, high or low

–

Stabilises lime & weak mortar masonry to prevent collapse

–

No Lost or falling masonry

–

The only temporary support equipment fully tested in multiples on brickwork

–

Supports all of the masonry, even in lime mortars

–

Guaranteed superior finish to a task

–

Versatile & Lightweight

–

No voids/traps in scaffolds

–

Also use when propping for total control of a task

–

Increases the variable & unknown S.W.L of bendable tongued prop attachments

–

Protection against minor collapse in-between props

–

Re-instates a load point to safely reduce the weight of the load

–

Allows a prop to be manoeuvred safely during a task

–

Safely minimising the number of props required

–

Pays for itself within two applications

–

Minimal Repair time

–

Easy To Store/ Fits in a tool bag

–

Reduced carbon footprint

–

Designed & Manufactured with British steel in Great Britain

–

Superior results and time saved

GUARANTEED

–

ALSO USE THE BRICK BRACE AS A SAFETY BELT WHEN PROPPING

–

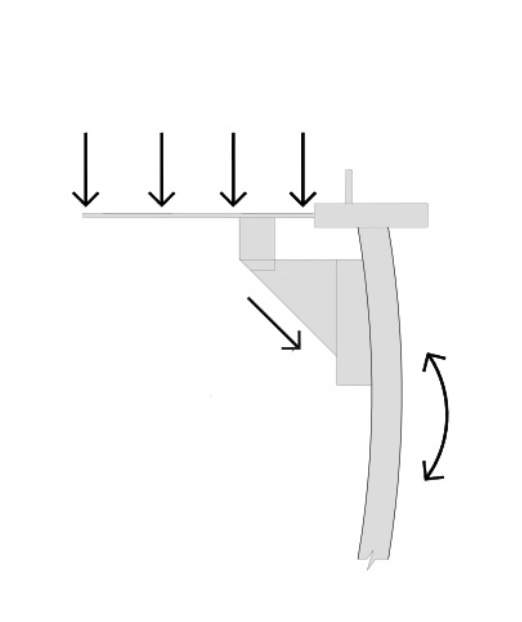

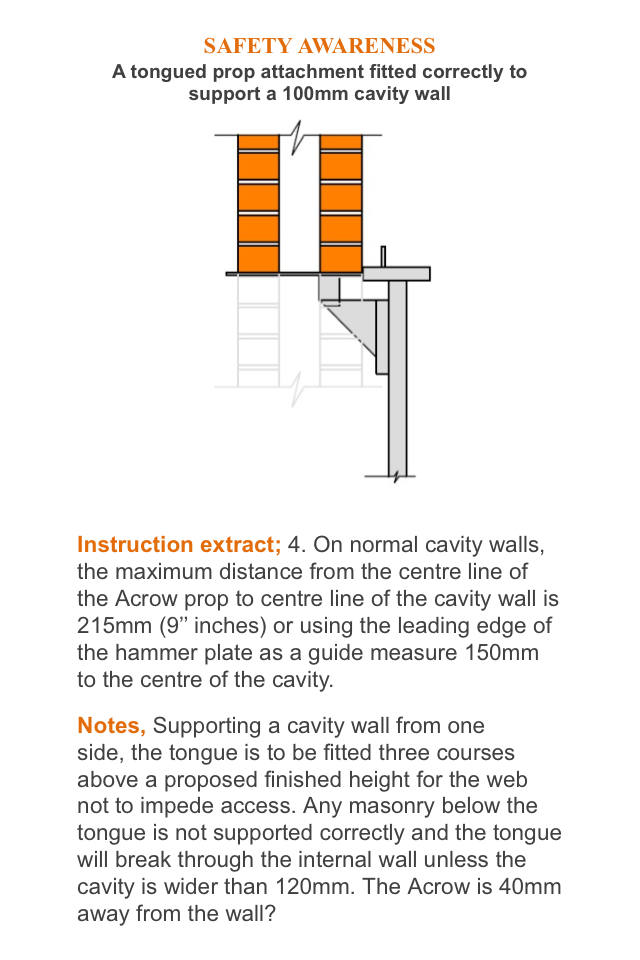

The traditional tongued prop attachment was designed in the mid 1980’s when a cavity size was only 50mm but due to changes in construction design a cavity has now doubled to 100mm and even up to 150mm upon newer properties, with open plan living accommodation also increasing the opening sizes within a typical residential extension.

Attempting tasks which require longer & wider steels with welded top/bottom plates for large cavities and still only using out of date Strongboy’s is where more problems of overloading through over extending even further from the wall to gain adequate access arise, the safe working load is almost halved when only using the end 100mm of the tongue.

–

The combined working load of an eccentrically loaded Acrow prop and tongued prop attachment varies from 340Kg down to 0Kg of which is reliant on the factors below;

A, the brand, size, condition and age of the Acrow prop.

B, the height an Acrow props inner tube is extended, the position & number of 14mm pin-hole perforations are showing above the outer tube.

C, the measurement of the eccentric load, from the central-axis of the Acrow prop to the centreline of the propped wall.

D, how plumb and how tight the Acrow prop is installed beneath the wall.

There is a critical difference between using sound engineering principles and using a product with a variable working load that do not address the laws of physics.

The TWf (Temporary Works forum) description of a Tongued prop attachment in the 2017 temporary works tool kit, part 10;

–

Steel plates (approx. 150mm × 350mm) that fit onto the head of an adjustable steel prop (‘Acrow’). The plates can be cut into the mortar joint above the new lintel. They will be positioned at relatively close centres (around 750mm) and rely on the brickwork arching between them. They can typically support loads of around 350kg (as the applied load is eccentric to the prop) and are generally used for openings up to around 3m wide, with heights less than around 3m. If an opening is to be formed in a thick wall, or the opening is wide, then a designed needling scheme would be required. The needles should be positioned not more than 1m apart and the load on each needle should be calculated.

–

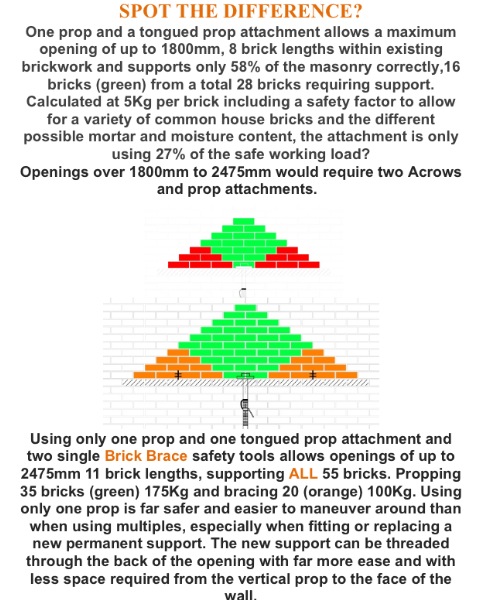

The main cause of collapse during masonry alterations is overloading due to not knoeing that the safe working load of propping equipment is variable.

Removing tongued prop attachments from the wall to gain fitting access decreases the safe working load.

–

Where fitted with a Strongboy or any other similar designed product an Acrow props safe working load decreases by at least 90%, from 3,400kg down to the maximum 340kg and can even reduce down to 0kg of which depends on the size & the working height of the Acrow prop, how plumb, how tightly fitted and how far the Acrow prop is positioned from the centre of the wall.

–

Without warning a Strongboy changes the direction of the load onto the side of the Acrow props inner tube of which is designed only for vertical loads, from the head plate down to the foot plate, which is why the Brick Brace should also be used when propping eccentrically.

An eccentrically loaded Acrow prop curves and loses height when overloaded or over tightened.

To prevent the inner tube from curving it should exit the outer tube no more than 50% when eccentrically propping; ensure to use the correct sized Acrow prop for the task ahead.

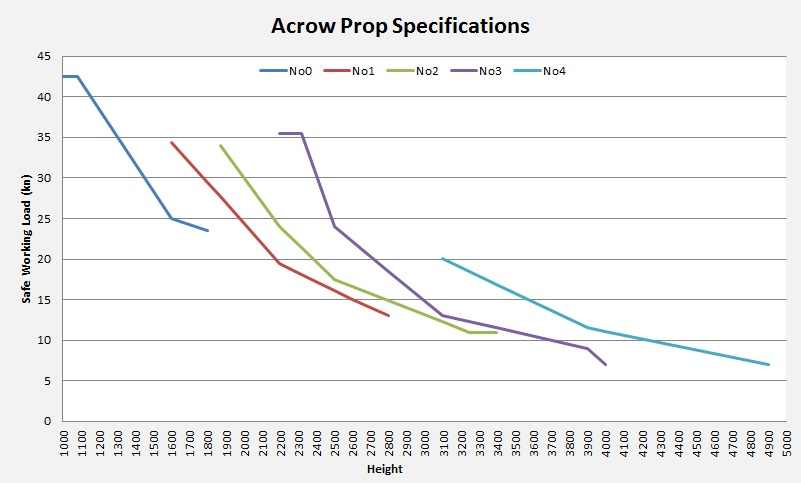

(Below is a graph showing the variations of an Acrow props Safe Working Load when concentrically loaded from head plate straight down to foot plate.)

Using the Brick Brace in-conjunction with the traditional propping methods reduces labour & repair time without cutting corners or compromising safety, supports the masonry in between props and also improves the unpredictable lateral strength that all existing propping methods rely on to work safely.

The Brick Brace Safety tool/system, weight charts, correct procedures & proven strategies address all the main causes of minor and major collapse to ensure future generations are taught safely & correctly.

–

NO LOST OR FALLING MASONRY & MINIMAL “MAKING GOOD”

Prop internally upon bonded 9″ to 13″ walls and brace externally for superior and safer fitting access.

Lime mortar 9″ masonry has very little lateral strength and can weigh over 600kg per square metre, (120 bricks plus mortar) which would require at least five Strongboy’s per linear metre (at 167mm centre’s) on wide openings upon a typical two storey residential property, this can weigh 1,440Kg per linear metre without roof loads which makes using Strongboy’s unsuitable for the task without also using the Brick Brace to stabilise the masonry beforehand and to reduce & share the weight of the load in uniform.

–

Reduce risk of minor & major collapse upon wider openings by bracing the masonry when dangerously removing an opening down to the full depth to gain sufficient access for genie lifts within a forest full of loaded Acrow props.

Also use as a safety belt above openings when propping or needling to reduce the weight of the load to prevent collapse from overloading & accidental knocks of loaded props from masonry removal, to safely minimise the number of Acrow props within the fitting area, to hold the brickwork in-between props and to also support the masonry as one whole piece rather than individual bricks as in the case of only using existing propping equipment.

–

Recent E-Bay feedback

“I can’t believe I’ve waited so long to use this product!! Brilliant.”

BRILLIANT! Saved a lot of time and the beam went in with very little effort and no lifting gear due to our scaffold platform. I would highly recommend this system and we will be using it for all opening works from now on.

J. Hoggard, Builder

East Riding Of Yorkshire

–

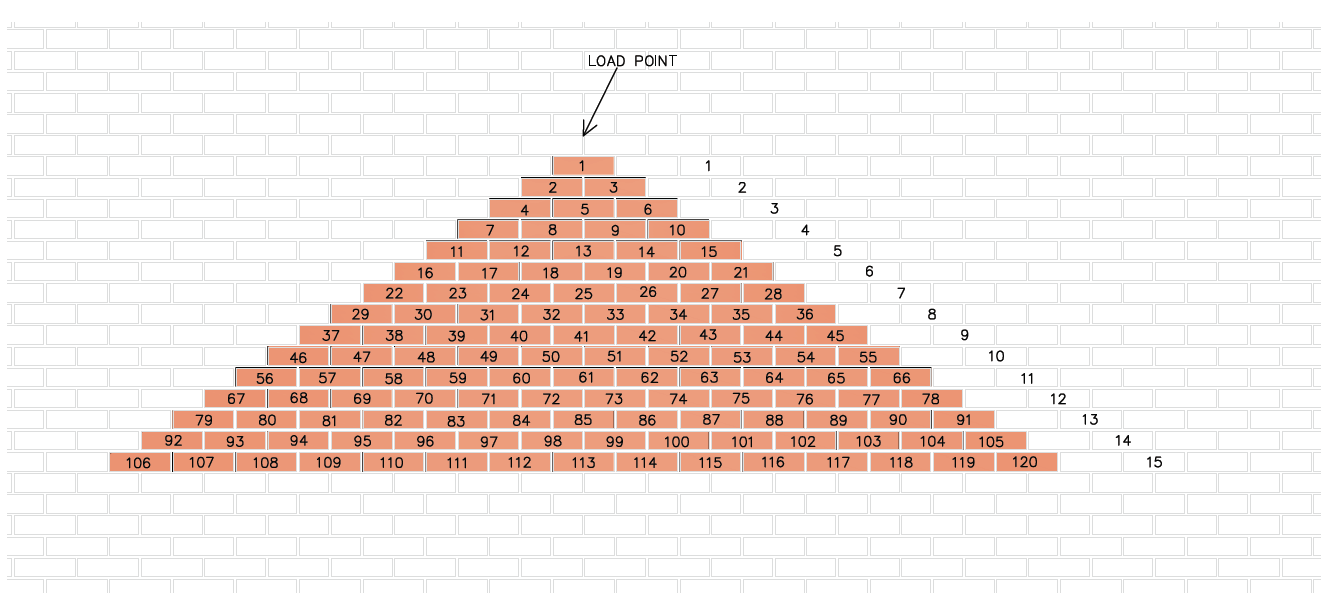

Load-Point

Which masonry requires support?

–

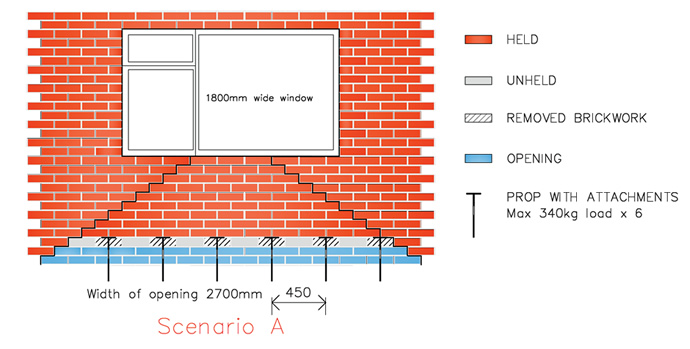

A 45 degree angle upon half bonded block work, a 35 degree angle in a Stretcher bond and a 25 degree angle upon a Flemish or English bond, from both ends of the opening, carrying up through the bed and perp joints to the central perpendicular joint where both angles meet is the location of a load-point.

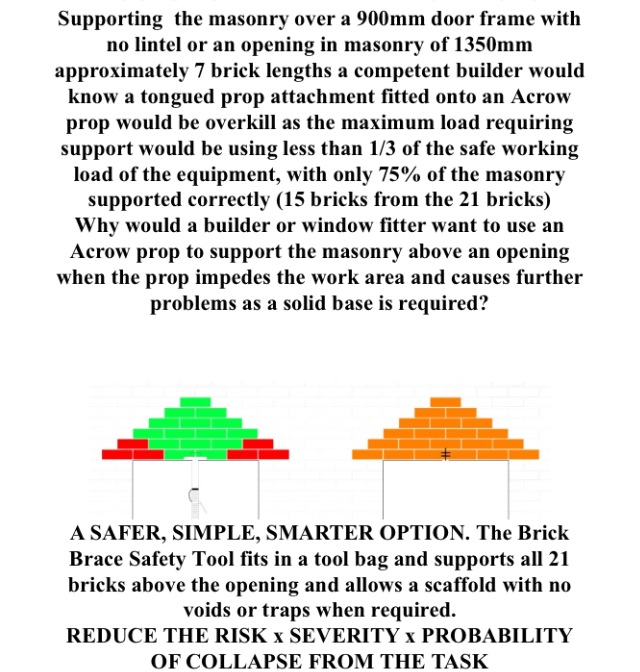

When an opening is made within an existing wall and a load point is intact, the triangle of brickwork above the opening is the only masonry that could collapse, therefore this is the only masonry that requires temporary support.

–

This small triangle of masonry is also what Strongboy’s were designed to support when fitted 900mm apart and used within the 215mm maximum eccentricity.

–

Upon larger openings within a typical two storey residential property and any of the 3 points of the triangle do not remain, this law changes and all of the weight of the storey height above will rest back over the length of the opening (including roof loads, when they apply) due to the masonry above not safely arching.

This masonry can weigh up to 10 times more in most cases than just the smaller triangle and is why Strongboy’s are so easily overloaded upon wider openings.

–

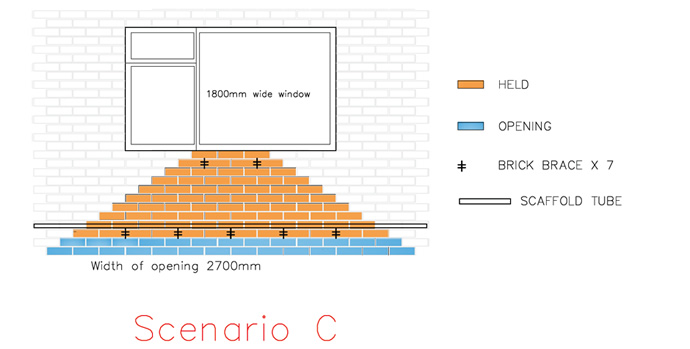

Fit the Brick Brace to reinstate a load-point, as shown within the drawing below to safely reduce the weight of the load back to the small triangle of masonry and to minimise the amount of impeding Strongboy’s required without dangerously overloading the equipment.

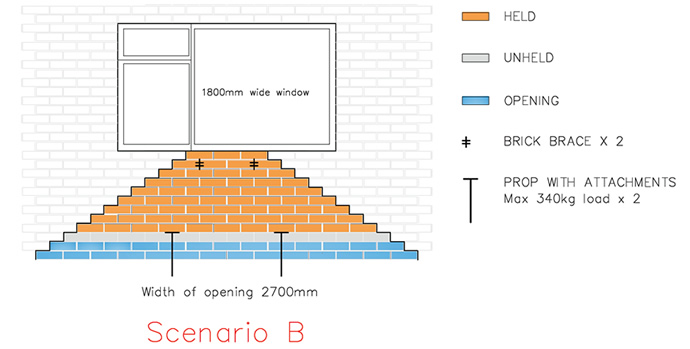

(Scenario C below, shows the Brick Brace Safety System being used within a lime mortar mix)

The Brick Brace Safety tool, weight charts, correct procedures & proven strategies address all the main causes of minor and major collapse during masonry alterations.

Please view our masonry weight awareness chart for further guidance.

A Strongboy was designed in the mid 1980’s when openings were smaller and a cavity only 50mm, due to changes in construction design a typical cavity has doubled to 100mm and 150mm+ upon newer properties for further thermal value and open plan living accommodation has vastly increased the opening and steel sizes within a typical residential extension.

Attempting tasks which require longer & wider steels with welded top/bottom plates for large cavities and still only using out of date Strongboy’s is where more problems of overloading through over extending even further from the wall arise.

–

We have studied temporary masonry support for many years, more than anyone before us, our fully patented method of strengthening masonry before any alterations take place is the further preparation required for safer and superior results, guaranteed or your money back.

–

Purchase & use with confidence after reading our 1,000 + E-bay feedbacks & Reviews.

One of eBay’s most reputable sellers.

Consistently delivers outstanding customer service.

–

Additional information

| Weight | 15.0 kg |

|---|

Johnny Hoggard –

BRILLIANT! Saved a lot of time and the beam went in with very little effort and no lifting gear due to our scaffold platform. I would highly recommend this system and we will be using it for all brick opening works from now on.

Colin harrison (verified owner) –

I have a two set of these and makes it so much easier to install steel beam/lintel, I’ve used it with just a single scaffold pole and the claps and works fantastically no dropped brick no cracked in the motor and no obstruction of acrows while trying to install your beam/lintel, I’ve since used it with a scaffold beam and the claps to fit an 5.8m 254×254 beam bolted to a 4.6m 254×254 return beam on a detached house, to do both beams I used a full set and a few claps from second set, I also used there propwise to support the internal wall. I can’t fault how they work and won’t be doing any beam installations any other way, even my architect was impressed how much of a span was achieved with the brickbrace and scaffold beam set up. I would true advise anyone thinking of buy these to do so you won’t look back.

S. Dunaway –

After taking the time to read and understand what the Brick Brace has to offer, I can now appreciate the impact this system can have on improving the safety of structural alterations. After all structural alterations are the only general construction based procedures where no training or advice is offered to any tradesman.

For me, Brick Brace is not just a product; it has provided an understanding of the task, with clear guidance on the limitations of all the equipment.

I also received very helpful advice and instructions from the guys at Brick Brace regarding my own project.

I challenge you all to find another company so invested in your own safety when it comes to structural alterations.