RESEARCH

An eccentrically loaded Acrow prop

No factor of safety, manipulated calculations and a variable working load is not safe. And if an investigation of collapse is complete only by finding fault with the builder when the risks of eccentrically loading Acrow props are hidden from the users view, it is missing the real story behind collapse; especially when an Acrow prop is designed only for concentric loads.

The existing view of the bad apple theory;

Builder error is a cause of accidents. To explain failure, you must seek failure and find the builder’s inaccurate assessments, wrong decisions and bad judgements.

Our view;

Builder error is a symptom of trouble deep inside a system. To explain failure, do not try to find where builder’s went wrong; Instead, find how their assessments and actions made sense at the time, given the circumstances that surrounded them.

AN ILLUSION OF SAFETY

Progress on safety based on the bad apple theory is a short-lived illusion. Focusing on individual failures does not take away the underlying problem; removing the bad apples fails to remove the real errors and fails to prevent similar accidents re-occurring.

–

So why would anyone adhere to the bad apple theory?

One is that it guards the hierarchy, it is simple to understand and cheap to implement. The bad apple theory suggests that failure is a temporary hiccup in an otherwise safe operation. Nothing more fundamental or more expensive needs to be changed.

–

To understand error you need to examine the larger picture in which these people work, dividing an operational system into a sharp end and a blunt end.

At the sharp end;

the train cab, the cockpit, the operating table, and the construction site; where people are in direct contact with the safety-critical process.

At the blunt end;

the organisations that supports, drives, and shapes activities; the railways/airline, hospital, equipment vendors/retailers, clients, Head office, Site Office, Structural engineers and regulators.

The blunt end provides the sharp end with guidance and resources; equipment, training, and procedures to accomplish what it needs to accomplish. However, at the same time it puts on constraints and pressures (“don’t be late, don’t cost us any unnecessary money, no holes in internal 1st floor walls, assumed calculations, etc”). Therefore, the blunt end shapes, creates, and even encourages accidents at the sharp end.

–

Looking for sources of failure far away from the builder at the sharp end is counterintuitive, as where you find that sources of failure lie really at the blunt end, calls into question the beliefs about safety of the entire system and challenges previous views.

Perhaps things are not as well-organised or well-designed as people had hoped. Perhaps this could have happened any time; or worse, it can happen over & over again with the worker at the sharp end accused of the fault, which is clearly out of their control when the risks are hidden and therefore, unidentifiable.

–

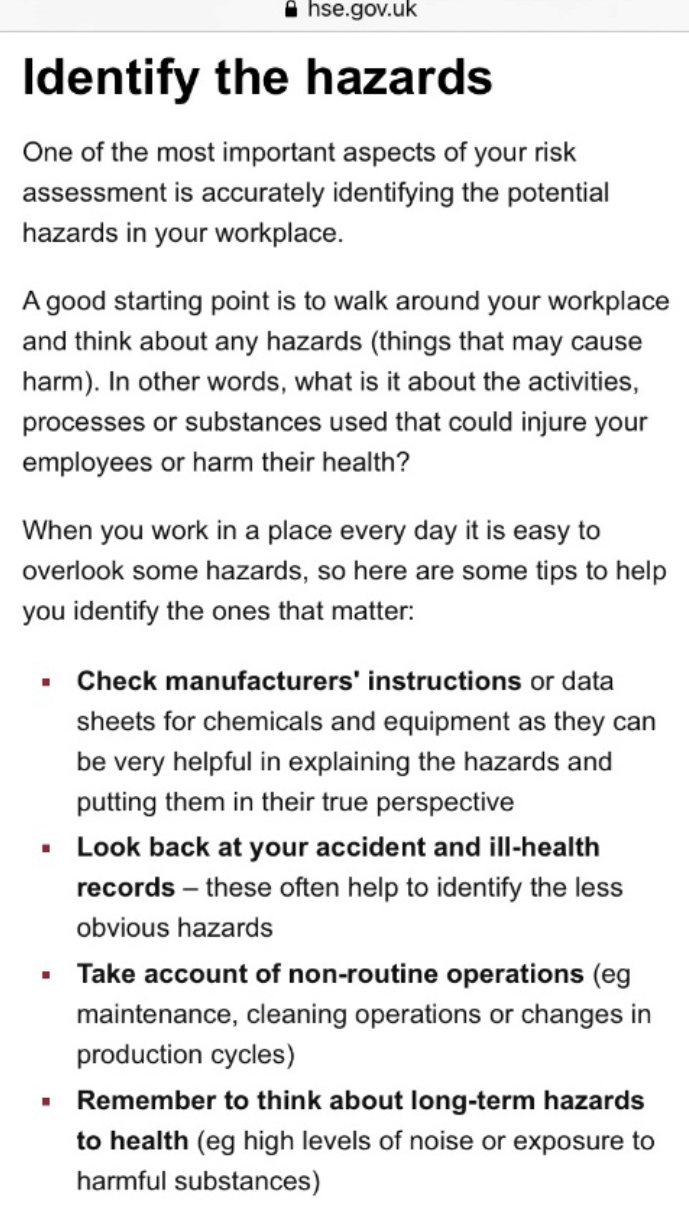

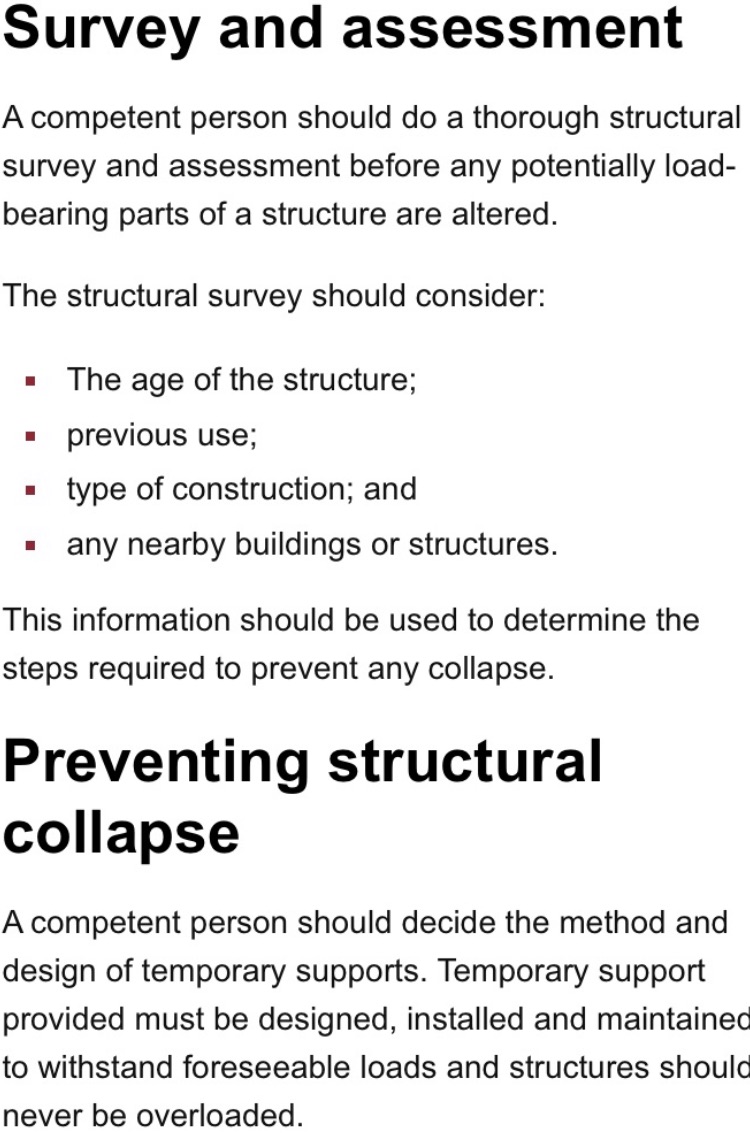

The H.S.E.’s interpretation of a competent person is; “Someone who has the necessary skills, experience and knowledge to manage health and safety.”

Due to inadequate testing and guidance, both the eccentrically loaded Acrow prop and tongued prop attachment have falsely eased a specialist task, of which has supressed the true level of knowledge required to alter masonry safely; as the risks are hidden and can’t be identified by the end user, deeming them insufficiently knowledgeable. However created by the negligence of the hierarchy at the blunt end.

The Brick Brace, our guidance, correct procedures, weight charts and proven strategies address the main causes of minor & major collapse when altering masonry and provides the knowledge to comply with the C.D.M. regulations 2015.

–

AN ERROR TRAP HAPPENING OVER & OVER AGAIN

–

ACROW PROP

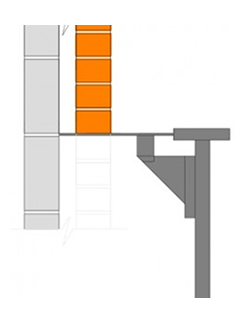

An Acrow props maximum safe working load is 3,400Kg and designed only for loads upon the central axis with a maximum of 25mm eccentricity from the axis, of which reduces the variable working load by 50%, maximum 1700Kg and reducing further depending on the size of Acrow prop and of the height it is to be used; as seen in the graph below.

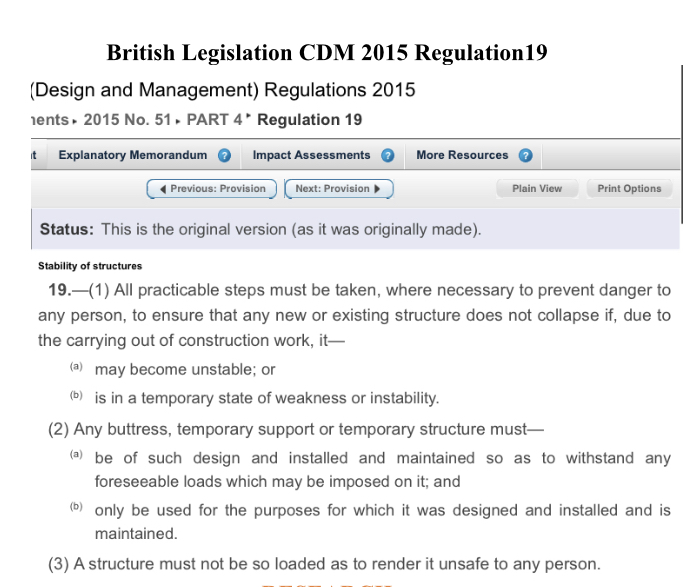

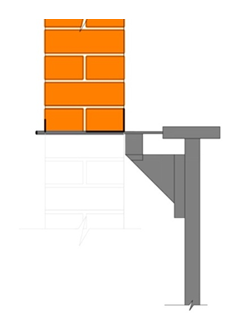

Vertical & Plumb Acrow props (in the process of being braced)

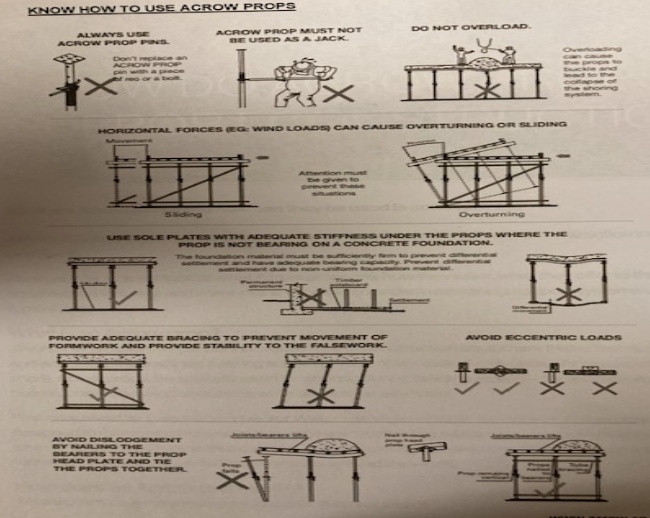

Visual Acrow guidance explaining how to avoid eccentric loads, 3rd drawing on 4th line.

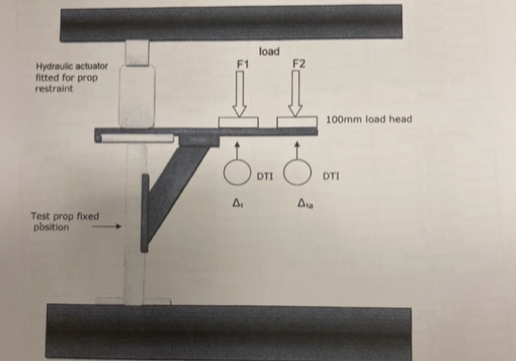

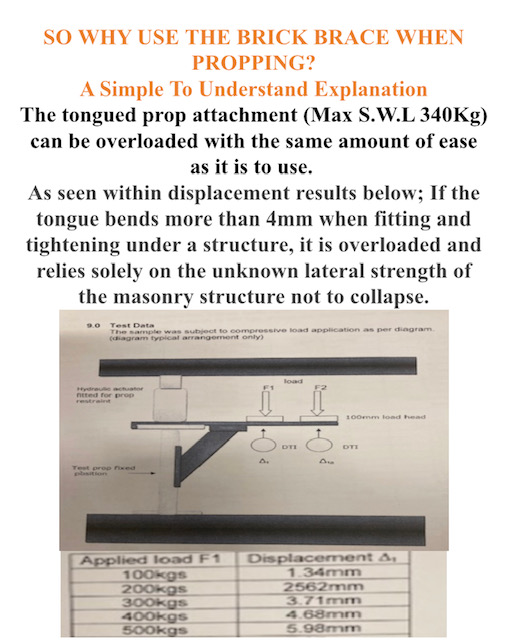

Testing Arrangement Of A Tongued Prop Attachment, (fitted to a short prop with no 14mm pin holes, approximately 400mm long).

The tongued prop attachment requires the use of an Acrow prop (max height 3metres) of which the test does not include and when used on-site it is not possible to use hydraulic actuators for prop resistance during a task as seen below with the tongued attachments destabilising the structure. The test only proves the attachment can be used upon a 400mm prop with no pin-holes and with an actuator to restrain the prop from movement, nothing more.

Only tested as a single part and NOT in multiples upon Acrow props or within masonry therefore the test is inadequate due to;

1 Not creating the correct on-site conditions to analyse the results to a satisfactory conclusion.

2 The stability of a structure is unknown due to not testing in multiples upon masonry as loads on-site are not uniformly distributed over an opening.

3 Without warning the product dangerously misuses an Acrow prop and isn’t within the British Standard of Acrow prop use or within the C.D.M 2015 regulations.

4 The generic calculation & assumed working load is not safe as it will vary when used upon different sized Acrow props and the different measurements of eccentricity as explained in previous research. When using the last 100mm of the tongue the working load is no more than 140Kg and is not safe as the bendable tongues and different torques on Acrow props can distort & destabilise a structure when attempting to gain more fitting access.

IDENTIFYING NON-TESTED HAZARDS

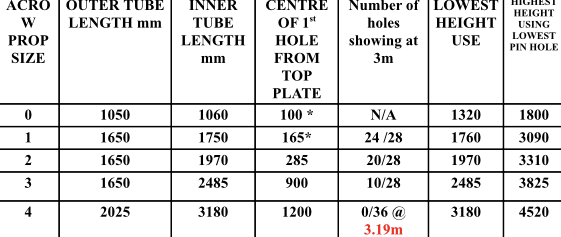

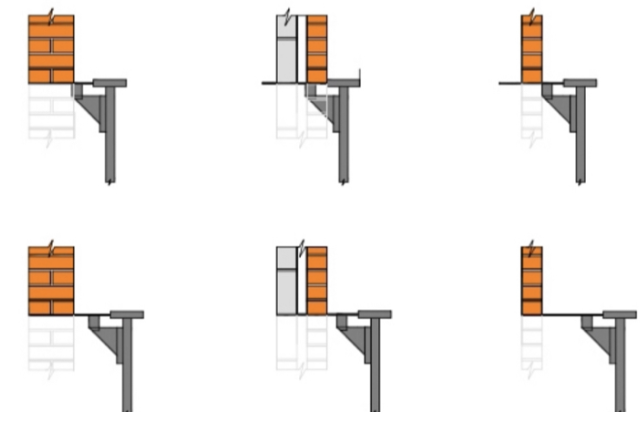

Acrow Prop Sizes from left to right; 0, 1, 2, 3 & 4

* Sizes 0 & 1; two 14mm perforations within the Inner tube are situated exactly where the force of the load from the web of an attachment contacts the side of the inner tube, creating a weak point which has never been researched or tested to find out the true safe working load which should include a factor of safety.

IDENTIFYING FURTHER RISKS AS A COMPETENT PERSON

VARIABLE

Oxford Dictionary Definition of the word variable; Not Consistent, not having a fixed pattern; liable to change.

Anyone that has travelled on a major motorway in GB understands the meaning of the word variable due to the warnings of variable speed limits.

When there is no written warning that the working load of a non-tested & misused Acrow prop is variable, it is not safe and becomes dangerous to the unaware user.

Due to a tongued prop attachment dangerously misusing an Acrow prop and no testing ever carried out on eccentric loading of the different sized Acrow props, there are four non-researched points that are problematic. The first is explained within the last page and the second is the buckling effect caused by the eccentric loading on to pin holes at the top of the outer tube where contact is made to the inner tube, as seen below.

The third is in-between the two points mentioned and varies within the many different possible measurements and heights of use; the inner tube is peppered with 14mm perforations on two sides for 14 different pin hole heights at 100mm centres, equalling 28 perforations along 1,400mm of inner tube of which is liable to dangerously curve to reduce the height unknowingly during a task, see photo below.

Photo from E-Bay Advert, Selling Prop attachments.

The fourth area of concern is the welded top plate, as it is only designed for a vertical & downward load from the top and not for a pulling downward/upward & sideways motion of which the tongued prop attachment creates when fitted & loaded, also seen in the above photo and as described in the visual guidance provided in page 2 of this research.

From the three sizes of Acrow Props available to use at the height of 3metres, all three are manufactured with the exact same length of outer tube. Another concern is that all three sizes (no 1, 2 & 3) have further pin holes for heights higher than 3metres. As no written guidance is provided at the point of sale/hire this becomes a problem of using a tongued prop attachment with an Acrow prop which elevates higher than 3m and is dangerous and not suitable.

When eccentrically used at the maximum height of 3metres the most suitable sized Acrow prop is No3 however Strongboy Ltd only sell size No1’s within their multiple contract packs for wider openings with further loads above.

Further testing and research into a reduced working load with a further factor of safety must be carried out, so not to continually compromise the safety of the user, the public and clients.

CONTRADICTION;

From the five sizes available, structural engineers say that the size no4 is not suitable for using with a tongued prop attachment, yet at a 3.19m working height it is the only size with a 375mm longer outer tube & without any perforations showing above the outer tube. If the H.S.E and structural engineers can explain why the size no4 isn’t suitable, then the answer/explanation would be the same for all sized Acrow props.

OLD OR NEW ACROW PROPS?

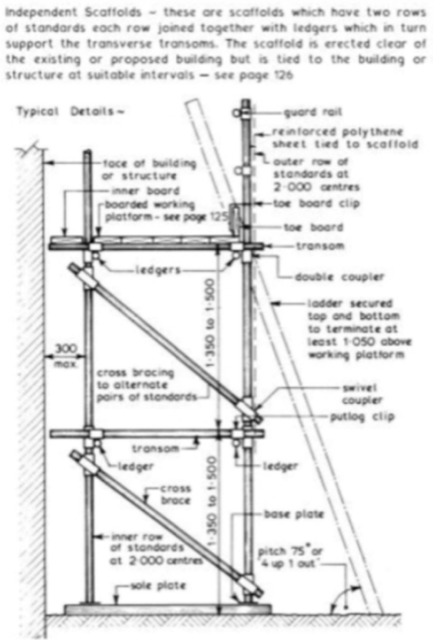

The strength of an erected scaffold is calculated differently, whether it is brand new scaffold or already used scaffolding parts. The assumed difference between old and new is calculated at a 10% deduction in strength when scaffolding is erected from already used parts.

No similar calculation is in place for old and new Acrow props, even when the vast majority of Acrow props are stored outside all year round in the same manner as scaffolding. All scaffold tubes require a finish to the metal, which is usually galvanised to prevent rusting or manufactured from aluminium, however the vast majority of Acrow props are only sprayed with one coat of paint.

A galvanised scaffold tube is 48.3mm in diameter and has a minimum wall thickness of 4mm & 5mm if the tube is manufactured in the lighter aluminium.

An Acrow props inner tube is also 48.3mm in diameter, but only has a wall thickness of 3.2mm which is 20% less than a scaffold tube and more prone to internally hidden rust due to being peppered with 14mm perforations. The circumference of an Acrow prop inner tube is approx. 152mm. with the two 14mm pin holes reducing the strength by 21.5% at every pin-hole height X14; throughout 1400mm of inner tube.

Holes are not recommended/permitted within scaffold tube as it would have no purpose, yet there are up to 28 holes (diameter 14mm) within the Acrow prop inner tube of sizes No 1, 2, and 3. See previous chart.

An independent scaffold has an inner scaffold board fitted eccentrically (with transoms a maximum 900mm apart & closer) inner board is for foot traffic only and is supported at a minimum of two points by regulated requirements and is an overall 325mm eccentric from the centre of an Upright tube and connected to a number of further uprights.

Typical independent scaffold lay-out

Typical All-Year Round Storage Of Acrow props

An Acrow prop is not fixed to anything when fitted with a tongued attachment and solely relies on the eccentric friction between the tongue under the propped masonry down to the foot plate at ground level. There are many different scaffold organisations in GB and no specialist temporary masonry support organisation, only the H.S.E with a little help from Istructe. Clearly shown within the research above; the individuals in control of scaffolding are more knowledgeable and safety conscious and more aware of the risks than the individuals in charge of temporary masonry support, who are at least 30 years behind due to not accepting the responsibility of the faults created in the mid 1980’s by past colleagues which did not identify the hazards of eccentrically propping from one side of a wall upon a dangerously misused Acrow prop.

Except for bracing a structure, no scaffolding tube is recommended to be used for temporary masonry support due to the strength issues however a dangerously misused Acrow prop with so many defects have been given the green light for masonry alterations by the H.S.E. when it should not have been.

Upon their website, the HSE provide more written advice and guidance of legislation for scaffolding than temporary masonry support even though training & registration with an organisation is required to carry out an erection of a scaffold and yet nothing is required for masonry alterations which is far more dangerous and difficult when carried out by someone that requires no registration or training.

H.S.E website guidance word count for Scaffolding= 1236 words.

Masonry Alteration word count = 335 words. 72% less Advice.

CONCLUSION

My researched & professional opinion is that the main causes of collapse during alterations is due to;

Inadequate and manipulated test results accepted when not even seen by the HSE and when the test only proves the working load of the product is variable,

Moving goal-posts to make a product more desirable for masonry alterations to save time and money during a project which has dangerously eased a specialist task and cost life in the process.

The H.S.E not understanding the dangerous relationship between the unknown & variable safe working load of the different heights of the four sized Acrow props and the further decreasing working load of increased distance from wall to prop when eccentrically propping with tongued attachments.

A severe lack of research of the hidden dangers for the end user to identify the hazards on-site correctly.

Inadequate guidance and 2 generations of the less knowledgeable teaching the next generation.

The retailers deceiving with visual marketing of strangely permitted further eccentricities, including false Acrow prop readings to make the tongued prop attachment more suitable when it’s not suitable, only more dangerous. The drawing below of which I believe to be beyond the rules of caveat Emptor.

The H.S.E setting a very low precedent within the manufacturing/retail of temporary masonry support equipment, allowing anyone with an ability to weld with no knowledge of the task to easily supply and sell masonry alterations equipment and not policing the problem to an acceptable level due to insufficient number of knowledgeable staff.

The tongued prop attachment being designed and calculated by personnel that have probably never carried out a task of altering masonry and do not understand the many dangers involved from true experience and not providing an agreed maximum opening size when first on the market.

A structural engineers generic assumed calculations of using a maximum safe working load for every project when the working load is variable and the H.S. E’s lack of masonry alteration knowledge and inability to change the mindset of the builder and incapable of addressing these issues without accepting responsibility of the faults.

All other causes of collapse derive from these un-acceptable mistakes.

Further Option

To resolve the problem of misusing an untested and non-suitable Acrow prop, a newly designed & strengthened variety of different sized props with a different sized top plate should be designed, tested and manufactured and made available with fewer holes to ensure the height restrictions of 3m and to reduce the higher risk of overloading, of which I have a design!

The law states that competence and knowledge is required to carry out masonry alterations yet no competence or masonry alteration knowledge is required or shown by the manufacturers, retailers or by the designers which dangerously assume temporary support calculations (structural engineers) or even the H.S.E that should be more knowledgeable and capable of accepting their wrong doings which has cost human life.

Builders will only ever be as competent as the temporary support equipment allows them to be and as knowledgeable as the teacher wants them to be. The teachers have hidden the faults so they can’t be identified on-site by the end user; through not ensuring the correct level of testing and not supplying the correct level of masonry alteration guidance or adequate written product instructions.

The HSE Website States:

RESEARCH

2b of regulation19.

“Temporary support must only be used for the purposes for which it was designed”.

An Acrow prop is not designed for eccentric loading of more than 25mm from the centre of the inner tube, therefore it should not be used with a tongued prop attachment to support a structure. As a competent person I believe it is the duty of the H.S.E to identify all of the risks involved by ensuring adequate testing and sufficient guidance within the instructions which cover the risks with appropriate warnings, this will prevent the builder from not identifying the risks on-site.

Please Note;

An existing company (Heaton Products) manufactures a stronger variety of size 1 Acrow prop (M.O.A.P) which is designed for eccentric propping with an increased inner tube size of 60mm+ and an increased outer tube frame of approximately 76mm. Should the construction industry take this route to reduce the number of accidents when eccentrically propping from one side of a wall? However, no test results are available for this product which needs to be examined more carefully especially when increasing the measurement of eccentricity to an amount of over 400mm. The manufacturing of this product also proves there is an underlining danger of using existing, non-tested eccentrically loaded, weaker sized Acrow props.

Curriculum

There will be no progress as no organisation is capable of taking temporary masonry support under their wing when it is so dangerously un-organised due to the mistakes created in the past and the vast majority of the education of altering masonry is only available through other builders and structural engineers of which both parties only make generic and dangerous assumptions of the variable working load as an eccentrically loaded Acrow prop can’t be calculated correctly; this is where many of the bad-habits and dangerous short cuts are taught.

No Progress Without Change

With the FMB, IOSH, CITB, HAE, ISTRUCTE, BRE, ICE, CROSS & CIRIA refusing to comment on any of my previous research and the H.S.E also unable to answer any of my questions due to being detrimental to themselves, masonry alterations is stuck in the 20th century due to a dangerous market monopoly of a product that is overloaded with the same amount of ease as it is to use and this is when all other sectors of the construction industry have made changes to increase the safety of the construction worker.

Any person involved within the construction industry that assumes no progress is required within temporary masonry support is not knowledgeable enough to be involved in such a task let alone comment or give advice. I am also astounded that the HSE staff do not understand the dangerous relationship between the variable safe working load of different sized Acrow props and the further decreasing working load of different distances from wall to prop when eccentrically propping with tongued attachments.

When fitted with a tongued prop attachment an Acrow props safe working load decreases by at least 90%, from 3,400kg down to an assumed maximum of 340kg and can even reduce down to 0kg of which depends on the size & the working height of the Acrow prop, how plumb, how tightly fitted and how far the Acrow prop is positioned from the centre of the wall.

–

Eccentricity & S.W.L of Acrow

Evidence below; taken from my previous research to explain why the team of individuals at the HSE do not understand the dangers of overextending an Acrow prop in height and the further measurements of increased eccentricity they allowed and then hide the risks, so the end user cannot identify.

No 4 OF OLD INSTRUCTIONS (including in-correct grammar)

- On normal cavity walls, the maximum distance from the the centre line of the ‘acrow’ prop, to centre line of the cavity wall or is 215mm ( 9″ inches). Or using the leading edge of the hammer plate as a guide. Measure 150mm to the centre of the cavity….

My expert Interpretation of instruction drawn below

NEW INSTRUCTIONS NOV 2015 (including in-correct grammar)

The Strongboy can be use on single or double skin walls where each leaf is up to 4 ½” (112mm) thick. If double skin, the maximum cavity is 2” (50mm). Ensure the blade of the Strongboy is fully supporting the second skin.

My expert Interpretations of new instruction drawn below

RESEARCH

The 340kg safe working load of the traditional Strongboy is calculated from the maximum eccentricity of 215mm which is the maximum measurement from the centre line of the Acrow prop to the centre line of the cavity wall.

Where the eccentricity is more than 215mm the working load reduces to an unknown quantity. Within the new instructions there is no mention of the maximum eccentricity. Strangely, all measurements within the new instructions are taken from the end of the oversized tongue, “If” this was a correct method to measure eccentric loads it is actually safer to support a 100mm cavity wall, (which is now not permitted) rather than supporting a 50mm cavity wall (which is permitted) as the measurement from the centre line of the Acrow prop to the centre line of the propped wall is 55mm greater on average and can be a staggering 150mm greater when using the XL Strongboy.

Total Eccentricity from centre of Acrow prop to the centreline of the 50mm cavity is now a staggering 365mm which is 150mm more eccentric than the old instructions and without any further reason, testing or explanation.

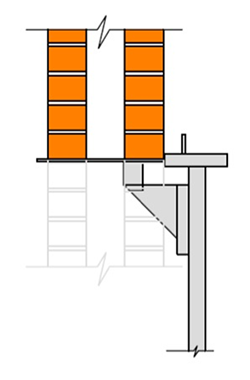

The three top drawings below, show the correct way to prop masonry within the old instructions and the three lower drawings show how the new XL Strongboy will be used within the new instructions.

The eccentricities are increased by over 50%;

9“wall = 75mm further eccentricity

50mm cavity wall = 140mm further eccentricity

4” wall = 135mm further eccentricity

CONCLUSION

The less knowledgeable HSE staff member maybe satisfied however they have failed their duties of care due to 25 years of misleading instructions, weak intervention of tightening up instructions after complaint by increasing eccentricity of a prop, still allowing inadequate testing results, permitting the dangerous misuse of an Acrow prop without any warning, providing minimal written guidance or advice, allowing structural engineers to use manipulated, generic out of date and assumed calculations and attempting to hide their faults & mistakes which in return has prevented the unaware builder (who in good faith purchase and hire the product from reputable retailers) from identifying the hazards when carrying out masonry alterations of which has created anti-competitive practice within the market place. The H.S.E accuse me of exhausting their complaints procedure when they haven’t attempted to address the issues of which have caused many avoidable accidents and deaths and left a nation of un-aware builder’s still dangerously misusing Acrow props which are not designed for eccentric loads.

My Recommended Changes to the Tongued Prop Attachment Instructions

The Strongboy instructions have supressed the true level of knowledge required to carry out masonry alterations as the risks are hidden and can’t be identified by the end user.

To reduce assumptions of correct use and to ensure the user can identify the hidden risks and is also aware that the guidance of a structural engineer is recommended if in any doubt, I recommend that written instructions with detailed drawings of maximum eccentricities are to be provided at the point of sale and to include Acrow prop guidance, different task scenario information, warnings of reduced and variable working loads and a warning that the product misuses an Acow prop. The research from the C740 should also be added within the instructions including the maximum opening size guidance they have described, as the informed should also inform the un-informed which is what instructions of correct use should be for.

Please note; the above boxed wording was written by myself but re-arranged by Keiron Tulley of CIRIA.

Please note; the above boxed wording was written by myself but re-arranged by Keiron Tulley of CIRIA.

Structural Engineers Calculation For Masonry Alterations

The test results clearly show variable safe working loads even when tested without the use of an Acrow prop however a structural engineer still uses the maximum safe working load of 340Kg with no factor of safety even though it is variable.

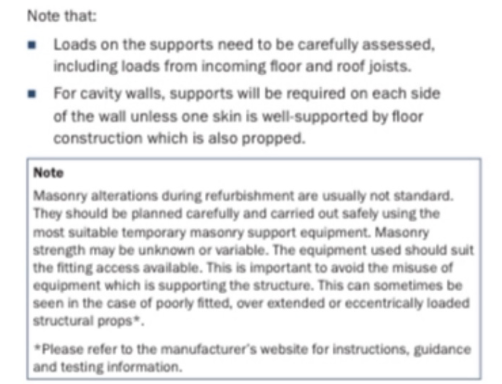

Further manipulation of test results advertised by the HAE (Hire Association of Europe)

Further Recommendations

To reduce accidents from the dangerous use of an eccentrically loaded Acrow prop, a competent Structural engineer must calculate each task separately and include the following recommendations/instructions;

A, Know the Exact height of which the Acrow prop is to be used from a suitable base and provide the guidance of the most suitable sized Acrow prop and include a factor of safety sum.

B, New guidance of the inner tube not extended more than half way from the outer tube of which reduces the higher risk of curving the inner tube and unknowingly overloading and de-stabilising the structure above. Where the S/E assumes the correct sized prop will not be used a further 50% reduction of the working load per prop should be calculated for a factor of safety.

Acrow prop Height Guide or similar when eccentrically propping

Size 0 Acrow Prop Maximum Height 1.6m

Size 1 Acrow Prop Maximum Height 1.95m

Size 2 Acrow Prop Maximum Height 2.65m

Size 3 Acrow prop Maximum Height 3.0m

C, When calculating and planning a task, a structural engineer/ temporary works designer must give a detailed description of the dimensions and size of steel/permanent support and the maximum measurement of fitting access from propped wall to Acrow prop to ensure the user does not reduce the unknown working load of an eccentrically loaded Acrow prop to a dangerous level. It is not possible to support both skins of a cavity wall externally as the majority of the load rests on the internal skin.

D, A reduced working load is to be used per prop upon wide openings with larger loads above and where the number of impeding props become un-controllable, a more suitable method must be used such as props and needles and using the Brick Brace to reduce the load upon bonded brick work and where suitable.

“Those Who Have The Privilege To Know, Also Have The Duty To Protect”.

DANGEROUS ENDORSEMENT

There is no certification, British standard or kite mark available for any temporary masonry support equipment as it’s not a permanent fixture, however scaffolding and Acrow props are also not a permanent fixture and yet both have a British Standard.

There is nothing more dangerous than endorsement from all parties involved making an agreement and moving goal-posts so that a tongued prop attachment does not require any British Standard or correct and validated testing. Yet again collusion has outweighed whistle-blowing at high level when the H.S.E has not seen any further tests to research.

–

Under a labour government the H.S.E was established on the 1st of January 1975 for the purposes of enforcing regulations in the workplace, except those regulated by local authority. This was provided to protect the worker and was not a money-making scheme to enrich the lives of structural engineers and greedy manufacturers of half-baked ideas of temporary support design at the expense of the builder’s safety.

Below are the changes within construction design of which I explained in detail to the HSE back in 2015 and for some un-explained reason the H.S.E permitted further eccentricities to counter-act the design changes of which has compromised the end user’s safety even more and without any further testing being carried out.

The traditional tongued prop attachment was designed in the mid 1980’s when the typical rooms & openings were smaller and a cavity only 50mm, but due to changes in construction design a cavity has doubled in size and over 150mm upon new properties for further thermal value and with open plan living accommodation vastly increasing opening sizes within a typical residential rear extension; therefore attempting tasks which require longer & wider steels with welded top/bottom plates for larger openings and wider cavities and still only using the out-of-date tongued attachment is where more cases of collapse occur due to overextending even further from the wall to gain enough fitting access.

It is wrong for so called professionals to allow such dangerous practice on our homes and at our place of work. The neglect & incompetence which the HSE staff have shown is also un-acceptable when it’s their duty to protect life and to minimise risk. Why have no lessons been learnt after Grenfell which caused 72 Deaths from manipulated product test results and also cost the tax payer 3.5 Billion GBP, and growing. The issues need to be addressed through-out the construction industry to ensure the correct level of safety is provided to the worker and to the public.

–

The tongued prop attachment doesn’t exist to be safe; it exists to make money for the manufacturer’s and to provide ease of a specialist task to cut costs, so a government body does not need to provide costly curriculum for the necessary training, this has suppressed the true level of knowledge required for the typical builder to comply with British legislation and to this day, is the main cause of collapse when altering masonry.

Besides safety there are multiple other objectives for the builder on a busy daily basis;

pressures to produce & to earn a living; to be on time; to get quick results; to keep customers/peers happy and they do not own the ability to juggle them in parallel with the demands of safety when the risks and uncertainties are hidden from view due to inadequate product testing.

You must assume that builders are doing reasonable things given their education & circumstances and doing their best given the complexities, dilemmas, trade-offs and uncertainties that surround them. Just finding and highlighting mistakes of inevitable accidents explains nothing. Saying what people did or did not do, does not explain why they did what they did when research shows that builders have been duped and wrongly educated by structural engineers, tongued prop attachment manufacturer’s and the HSE.

The reason of a human error investigation is to understand why actions and assessments made sense to people at the time. The whole investigation will need to look closer at the failures within the structural engineering organisations and the HSE construction team of which have failed the worker within the field of temporary masonry support due to a mixture of possible corruption, a lack of competent staff at the H.S.E and a work overload due to peer pressure from above and insufficient government funding. The construction industry keeps the country afloat and the workers within the industry deserve more protection and education.

–

Human error is not random, it is systematically connected to features of people’s tools, tasks and operating environments. Human error should not be the conclusion of a HSE accident investigation, but only the starting point.

–

COMPETENCE

Competence is a legal requirement to plan, design and/or alter a masonry structure, but how do you ascertain the true meaning of competence when the vast majority of structural engineers & temporary works designers already assume they are competent enough to plan and design a project with non-tested eccentrically loaded Acrow props and tongued prop attachments?

The H.S.E’s interpretation of a competent person is;

“someone who has the necessary skills, experience and knowledge to manage health and safety.”

We believe the HSE staff members of the now disbanded “construction safety team” and the staff at Istructe, of whom the HSE refer to for guidance, have both proven they lacked the skills, experience and knowledge to manage health and safety; when they didn’t evaluate the correct factor of safety calculation for the combined use of the Acrow prop and tongued prop attachment and accepted a number of dangerous discrepancies and differences between one individual product test and the use of multiples of the products on-site.

Between 2010-2020, The HSE website stated that;

“The main cause of collapse during masonry alterations is overloading equipment due to the lack of awareness of the equipment capacity and the underestimating the weight of the load.”

Whether this is through incompetence or greed, either way, both parties have created the accidents of overloading, by not fully understanding the critical difference between a factor of safety sum being calculated from the maximum safe working load, rather than from the minimum breaking strength and when the working load relies on the variable measurements of both the variable height of an Acrow prop and the measurement of eccentricity of the tongued prop attachment; of which it is not possible to calculate in a safe manner without adding the correct factor of safety sum after both products are tested together in multiples.

The main cause of collapse during alterations is avoidable, however it becomes very difficult to avoid when the combined organisations of authority refuse to resolve the issue; by concealing their predecessors’ mistakes and accuse competent individuals, (with the solution) of exhausting their complaints procedure when questioning their wrong doings since 2014. Their inability to correct the problem without accepting responsibility has generated the same reoccurring accidents, which is now in its third generation of workers, as it’s not possible to calculate the working load of both products together within the laws of physics from only the previous tests and most certainly not by either the unaware builder on-site or by a structural engineer/temporary works designer with the generic and assumed calculation methods they utilise from the unacceptable doctored testing results and incorrect method of the factor of safety sums.

–

The, That’ll do! Approach

How a structural engineers generic and assumed safe working load calculation, with an unrealistic factor of safety sum and inadequate equipment instructions has reduced the required level of competence of the tongued prop attachment user.

Both employers and employees working within the construction industry can only discharge their obligations under British legislation (C.D.M 2015) to the extent that the relevant information provided by manufacturers and the guidance of both the structural engineer and the H.S.E allows them to be. Where the information and guidance are either assumed, absent, doctored, or insufficient, as would generally appear to be the case with regards to both the eccentrically loaded Acrow prop and the tongued prop attachment, it is not possible for these obligations to be satisfactorily met. In particular the self-employed builders who appoint themselves as competent persons without even knowing they have appointed themselves as competent; simply by planning, designing and/or altering a structure due to either a severe lack of guidance provided at the point of sale and/or insufficient guidance provided by a structural engineer and the HSE. These workers, are not in possession of sufficient information to be judged truly competent and to no fault of their own, as they have purchased both the product and assumed/generic guidance in good faith from reputable retailers and structural engineer/temporary works designing companies of which the guidance is also dangerously endorsed and promoted by the HSE.

Sufficient/in-depth guidance for both products are not readily available to allow workers to make informed decisions and/or to identify the risks to an acceptable standard, especially when the hazards are unusual and hidden from the workers view; as they are concealed within the products testing un-certainties, flaws and faults.

Both products lack basic information about compatibility with each other and/or an approved configuration of use. The out-dated and manipulated maximum safe working loads are quoted for both components individually and not for use together of which has created a false sense of security to the end user.

Inadequate Design/Safety Factor calculations and no Working Load Limit (WLL) is used, when the existing and out-of-date, maximum safe working load is clearly taken at a measurement of 215mm of eccentricity of the old/redundant written instructions. However the increased measurement of eccentricity within the new written instructions is now 365mm, (150mm further eccentricity). This working load is clearly variable due to a greater distance of eccentric loading, (further from the Acrow props central axis) and is clearly insufficient and requires both products to be tested together to clarify an acceptable working load limit of which should include a correct factor of safety calculation, normally X10. This will prevent further accidents and will also protect workers, clients and the general public as it is not possible to manage health and safety when a product is supplied with hidden risks and incorrect guidance and is permitted to be used upon an already dangerous task of altering an occupied living accommodation structure and especially when open plan living design has increased the size of openings within a typical rear extension of a property. A structural engineer providing and deceiving a client with false information/guidance that is purchased in good faith, is not only dangerous but also fraudulent.

THE LEVEL OF COMPETENCE REQUIRED TO MASTER STRUCTURAL ALTERATIONS

A combination of skills and knowledge with the ability to identify all of the risks, including the risks which are hidden from view and not within the warnings of the written instructions.

The knowledge to take the correct action to eliminate the risks and the ability to sufficiently control the risks that can’t be eliminated.

Having the knowledge and ability to be completely certain and not to assume.

The ability to read and understand architectural/structural engineer drawings and to ensure the assumptions which are made by either party are correct, with a further ability to question both parties when their assumptions are incorrect, as one missing detail or change can lead to a list of further required changes.

The experience of knowing every project requires detailed planning upon its own merit due to each task being different and possessing the ability to use a variety/combination of temporary masonry support equipment most suitable. (See our planning a task guide for further information on the different possible scenarios at the end of this document).

Further factors that can increase the required level of competence, are good;

Leadership and communication skills.

Reading skills.

Attitude.

Knowledge of both British legislation and of the ever-changing building regulations.

Awareness to the finer & minor details.

Ability to adapt to necessary progress.

Understanding of how masonry acts above an opening and why masonry collapses, to prevent it from happening.

The factors that reduce the required level of competence are;

Insufficient warnings, inadequate guidance & misleading information, no product help-lines and manufacturers/retailers using Caveat-Emptor to extremes and taught bad habits.

Inferior or minus safety factor sums and the dangerous exchange of a structural engineers’ generic assumption of maximum safe working loads of which has prevented the end user from identifying the risks of overloading.

REQUIRED TEAM SKILLS

Bricklaying and carpentry skills to ensure remedial works, the “making good” and structural works are carried out within the building regulations and to ensure stability of the structure throughout the process and ensuring the materials, masonry & mortar mixes are suitable and match the specifications within the plans/drawings and that also match the existing structure for aesthetic purposes.

FURTHER KNOWLEDGE REQUIRED TO PREVENT OVERLOADING

The main cause of collapse during structural alterations is overloading equipment due to;

Underestimating the weight of the load and inadequate awareness of the increased weight of shockwave loads which are created through instability of a structure.

Not being aware that the load over openings without a load-point is considerably more than only the triangle of masonry over openings with a Load-Point intact.

Not understanding that when moving eccentrically loaded props further from the wall to gain sufficient fitting access will reduce the working load limit to an unknown quantity.

A lack of, or no preparation/remedial works to prevent collapse from overloading equipment.

Unaware that an Acrow prop is designed for concentric loading upon the axis only, with a maximum eccentricity of 25mm (and is not within the CDM 2015 regulation as stated in section19, 2b when extended further than 25mm).

Not knowing that equipment capacity is variable due to;

The combined working load of the misused Acrow prop and tongued prop attachment varies from 340Kg down to 0Kg of which is reliant on the further factors below;

A, the size, brand, quality, condition and age of the Acrow prop.

B, the height an Acrow props inner tube is extended and the number of pin-hole perforations that are showing above the outer tube.

C, the measurement of the eccentric load from the central-axis of the Acrow prop to the centreline of the propped wall.

D, how plumb and how tight and secure the tongued Acrow prop is installed beneath the wall.

When the working load of both combined parts vary considerably and the weight of the unknown dynamic loads of a structure can increase to extremes, it becomes quite obvious that collapse is more than a possibility when only propping from eccentrically loaded bendable tongues upon a misused Acrow prop. There is a critical difference between using sound engineering principles and using products with variable working loads that do not address the laws of physics.

REDUCING RISK

Structural Instability, vibration, unknown or further dynamic loads and inadequate or no remedial works creates a higher risk of overloading. Learn how to strengthen a structure to prevent sudden shockwaves reaching the bendable tongues to significantly reduce the risk of collapse.

Make it part of the required remedial works preparation to prevent collapse from overloading as the load of a braced bonded brickwork structure weighs considerably less than the load of an un-stable bonded brickwork structure.

To perform structural alterations to a superior standard, each project is to be planned upon its own merit to ensure the correct variety/combination of equipment is chosen.

The Brick Brace provides the missing factor of safety, stabilises the structure to reduce the load, supports the un-held masonry in-between props, (to prevent falling debris) and provides the correct and further scaffolding/fitting/working access without overloading.

Adapt safely to the Brick Brace by fitting over a proposed brickwork opening before propping to eliminate partial collapse in-between props, to prevent sudden shockwaves of increased loads onto the bendable tongues and significantly reduce the risk of collapse from equipment failure.

Ensure the correct space/access for scaffolding to carry out a task within the working at height regulations 2005.

The structural engineer, builder or temporary works designer that assume the safe working load is still 340Kg when using the last 100mm of a tongue of an attachment, does not own the true level of competence required by British Legislation; of which is not necessarily their fault, but the end result of The HSE construction team not having the competence to provide correct guidance or to manage the safety issues of the tongued prop attachment. They lack the knowledge to know the severe difference between a masonry load bearing close to the web of an attachment and the load upon the end of the tongue, as clearly seen within the test results.

CONCLUSION

Authority without the correct level of competence is dangerous to the public. At this moment in time the HSE staff and structural engineers have failed their duties of care, as allowing the typical builder, with even the mildest hidden disability to struggle within the construction industry, when all that is needed for success are appropriate accommodations and explicit instruction, is no different than failing to provide a ramp for a person in a wheelchair.

–

Martin Powell, Chief Executive of ISTRUTE,

Paragraph of his response to our research 27/09/2021

“Due to liabilities and conflict of interest a structural engineer cannot design the temporary works for a contractor. As such it is not usually considered to be part of a structural engineer’s normal brief. We recognise that there can be a few exceptions and a structural engineer will be asked to be involved, for example party wall issues, but it is not standard practice. Furthermore, when structural engineers do undertake such work, they do not usually specify what product is used. It is the builder who will use their preferred system and the structural engineer is there to support/guide their client.”

–

The above response only proves that structural engineers have, in the past, endorsed dangerous misuse of an Acrow prop and without providing sufficient guidance of the variable working load which in return has created a dangerous market monopoly and prevented further and essential equipment joining the market place. To guide a builder with inappropriate or non-suitable equipment, then calculate with a set maximum safe working load when it varies is not acceptable. There is a critical difference between using sound engineering principles and reckless behaviour which doesn’t address the laws of physics.

MASONRY ALTERATIONS

THE TASK THAT THE H.S.E FORGOT!

To prevent/reduce the risk of accidents there are over 20 H.S.E leaflets available for the “busy builder” which provide up to date guidance from ground excavations to avoiding overhead power lines, however there is “still” not one word of H.S.E guidance available for masonry alterations, which is the most under researched, difficult and dangerous task within the Construction industry.

–

Propping a masonry wall during alterations is far more difficult & dangerous than using a ladder, so why do the H.S.E think it’s acceptable to provide a seven page leaflet on how to use a ladder and yet they do not provide any masonry alterations guidance when the vast majority of residential extensions require masonry alterations and when they have improved the majority of simple work procedures since the 1980’s, is this due to their lack of temporary masonry support knowledge or is it their inability to correct the situation without accepting the responsibility of the fault of which they have helped to create by allowing misleading Strongboy instructions and also allowing incorrect and misleading procedures for over thirty years?

–

H.S.E “busy builder” leaflets website link;

http://www.hse.gov.uk/construction/areyou/builder.htm

–

“Safe use of ladders” H.S.E PDF link;

http://www.hse.gov.uk/pubns/indg455.pdf

–

WARNING!

A Class System Is In Place;

To please a client an architect has the artistic freedom to design & draw any new opening size they wish within existing masonry, with a few lines and a rubber and with no care of how it is done in real life.

A structural engineer can provide the method of using Strongboy’s by using an assumed, out of date calculation that doesn’t cover the stability of the existing masonry; this may save time by cutting corners but also compromises the builder’s safety as the method doesn’t give the correct fitting work access without dangerously overloading the structure due to a variety of different factors of which can’t be calculated safely.

the builder/contractor can purchase or hire Strongboy’s which are supplied with no written guidance and are sold by a vast majority of retailers with zero masonry alterations knowledge, and when the accidents of overloading continue to reoccur only the builder is at fault and fined/imprisoned for corporate manslaughter when collapse causes a fatality.

–

We recently asked the institute of structural engineers;

“How is it possible for a structural engineer to design a task safely with Strongboy’s when the safe working load varies due to misuse of an Acrow prop, from 340kg down to 0kg of which depends on the size of the Acrow prop used, which pin-hole height is used, how tightly the Acrow prop is fitted, how plumb and how far the Acrow prop is fitted from the centre of the wall”?

&

“Can you confirm that the new instructions of a Strongboy are acceptable and do not require any revision? And can you also confirm the market monopoly of the Strongboy and the misleading instructions have not fixed the typical builders and retailer’s mind-set and stopped essential temporary masonry support equipment join the market place”?

THEIR RESPONSE

“The Health and Safety Panel has discussed in great detail and over many e-mails the comments that you have raised. The Panel has taken the time to discuss the situation and the position of the Institution. With that the Panel thanks you for your query.”

“As a learned society the Institution exists to promote the art and science of structural engineering and does not comment on the efficacy of proprietary products.”

–

The temporary works forum, C.R.O.S.S, I.C.E, HAE, CITB and the H.S.E also refuse to answer our questions.

–

Not commenting on the dangers of a Strongboy is why collapse is such a reoccurring theme on site. Endorsing and promoting the Strongboy by designing temporary works with the product when they’re not suitable for a task and not providing warnings or correct procedures in writing to the paying contractor and also allowing misleading instructions is far from a science or an art form, only dangerous & incompetent.

–

The values of The Institution Of Structural Engineers

Professional standards

We endeavor to ensure that our members are highly skilled and work to the highest level by maintaining a commitment to professional standards within structural engineering.

We strive for continued technical excellence; advancing safety and innovation across the built environment.